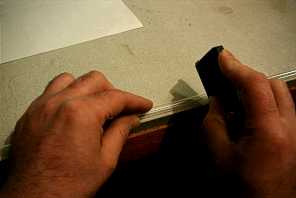

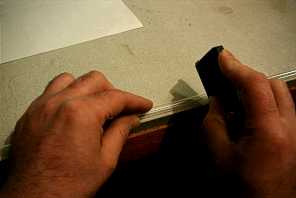

I found that 8mm diameter tube is a good size to practice with. In this example, I take

a half meter length of tube and rest it on the very edge of the work surface. I hold the

tube steady with one hand and take the knife in the other hand.

I found that 8mm diameter tube is a good size to practice with. In this example, I take

a half meter length of tube and rest it on the very edge of the work surface. I hold the

tube steady with one hand and take the knife in the other hand.

| Previous Page | Glass Blowing Menu | Main Menu | Next Page |

|---|

I found that 8mm diameter tube is a good size to practice with. In this example, I take

a half meter length of tube and rest it on the very edge of the work surface. I hold the

tube steady with one hand and take the knife in the other hand.

I found that 8mm diameter tube is a good size to practice with. In this example, I take

a half meter length of tube and rest it on the very edge of the work surface. I hold the

tube steady with one hand and take the knife in the other hand.

It is best to run the knife across the tube once. It should not be sawn back and forth.

One sharp scratch is sufficient. The scratch should be 3 to 4mm long and at right angles

to the tube.

It is best to run the knife across the tube once. It should not be sawn back and forth.

One sharp scratch is sufficient. The scratch should be 3 to 4mm long and at right angles

to the tube.

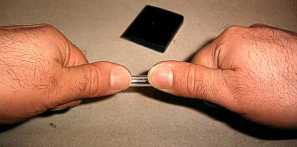

I grip the tube with both hands, with one thumb either side of the scratch. I hold it with

the scratch and my thumbs facing towards me.

I grip the tube with both hands, with one thumb either side of the scratch. I hold it with

the scratch and my thumbs facing towards me.

I pull the tube gently length ways as if trying to stretch it and at the same time bend the

ends of the tube away from me and the scratch towards me. I find this is best done as one

swift action. The tube usually severs cleanly with a satisfying click.

I pull the tube gently length ways as if trying to stretch it and at the same time bend the

ends of the tube away from me and the scratch towards me. I find this is best done as one

swift action. The tube usually severs cleanly with a satisfying click.

The freshly severed end of a tube is sharp and prone to damage. To make it stronger and

safer, it can be rounded over.

The freshly severed end of a tube is sharp and prone to damage. To make it stronger and

safer, it can be rounded over.

The air on the burner should be fully open and the gas turned up to a low to medium sized

flame. The severed end of the tube is then slowly introduced to the base of the flame at

a steep angle so that the end gets the most heat. The tube is then slowly rotated

in the flame. When the glass softens, the flame turns red and then an orangy yellow.

The tube can then be removed from the flame and allowed to cool slowly.

I find that Careful annealing is not normally required after rounding the end of a tube

because it is of uniform thickness and cools evenly. It should not be placed on a cold

surface when it is hot though. It is preferable to place the hot end in the annealing

tin.

This is the end of the tube after it has been rounded over. It is now stronger and safer

to handle.

This is the end of the tube after it has been rounded over. It is now stronger and safer

to handle.

A more advanced and versatile method of cutting glass tubing is described here.

| Previous Page | Glass Blowing Menu | Main Menu | Next Page |

|---|